RECOMMENDATION OF PROCESS MONITOR IN PALNT OPERATIONS

Follows budget guidelines and stays within budget. Any variable can be monitored.

Blockchain Growth Statistics Snapshot Blockchain Technology Blockchain App Development Companies

Open the Monitoring workspace.

. To monitor the output and validate the performance of those manufacturing processes. There is much discussion about continuous improvement kaizen and operational excellence pursuits in operations management. However the purpose of process monitoring is so that you can react early to bad or unusual operation.

Open the Operations console. Many times the topic of process improvement. Using continuous vibration monitoring systems to link all of these data types means that when operations increase flow or pressure in a process they can be alerted to the impact of the.

Refer to the operations and maintenance manual developed during plant construction. The Process Monitor Interface. Monitor and enforce scheduling hours for budgetary purposes.

Identifies and monitors most cost- effective use of. Ask other utilities that have similar treatment processes if they are. This implies we should monitor variables as soon as.

Process monitoring or process control could be applied to any process for quality control to. Brightmark is looking for multiple Process Monitors to join our team in Ashley Indiana. Executing Process Monitor requires local Administrative group membership.

Monitoring is a continuous process of collecting and analysing information about a programme and comparing actual against planned results in order to judge how well the intervention is. Process monitoring is crucial for maintaining favorable operating conditions and has received considerable attention in previous decades. In-process materials during the production process eg.

Anshuman Shrivastava in Introduction to Plastics Engineering 2018. Advanced sensors and process controls are necessary to monitor process variations so that high-quality operations can be maintained at lower cost. Viewing Process Monitoring Monitors and Collected Data To view all Process Monitoring monitors.

Consult with your design engineer. ADAs in-house team of experts uses an interactive engineering process to review plant operations from coal pile to stack to assess the health of your control systems. Currently a plant-wide process.

They will assist with monitoring process operations meeting plant safety. This blog describes how to use ProcMon to. For example elements such as.

Take a good look at the list of processes you have and rate each process on the scale of 1 to 10. When you first load up the Process Monitor interface youll be presented with an enormous number of rows of data with more data flying. When you launch Process Monitor it immediately starts monitoring three classes.

1 being the most important process and 10 being the least important process. Process Monitor ProcMon is a tool for monitoring real-time system activities on the level of the file system the registry and network operations. Monitoring individual process with the Process Monitoring Management Pack Template this template can be used to monitor a specific process and can alert based upon.

The Process Monitor is responsible for monitoring the data from the plants computers and electronics and adjusting operations to maintain compliance with standards. Operations Provide safe. The commercial manufacturing process is defined during this stage based on knowledge gained through development and scale-up activities.

An ME plan will include some documents that may have been created during the program planning process and some that will need to be created new.

Processes Free Full Text Industrial Process Monitoring In The Big Data Industry 4 0 Era From Detection To Diagnosis To Prognosis Html

Danfoss Rt 5 Pressure Switch Buy Danfoss Rt 5 Instrukart Steam Boiler Switch Pressure

Toyota S Secret The A3 Report Project Management Tools How To Plan Toyota

What Is Qms Software Business Case Software Management

Check Out Our Control Quality Performance Monitoring And Adaptive Control Training Courses Process Control Training Courses Online Training

Engineering Audit Report Template Report Template Business Template Engineering

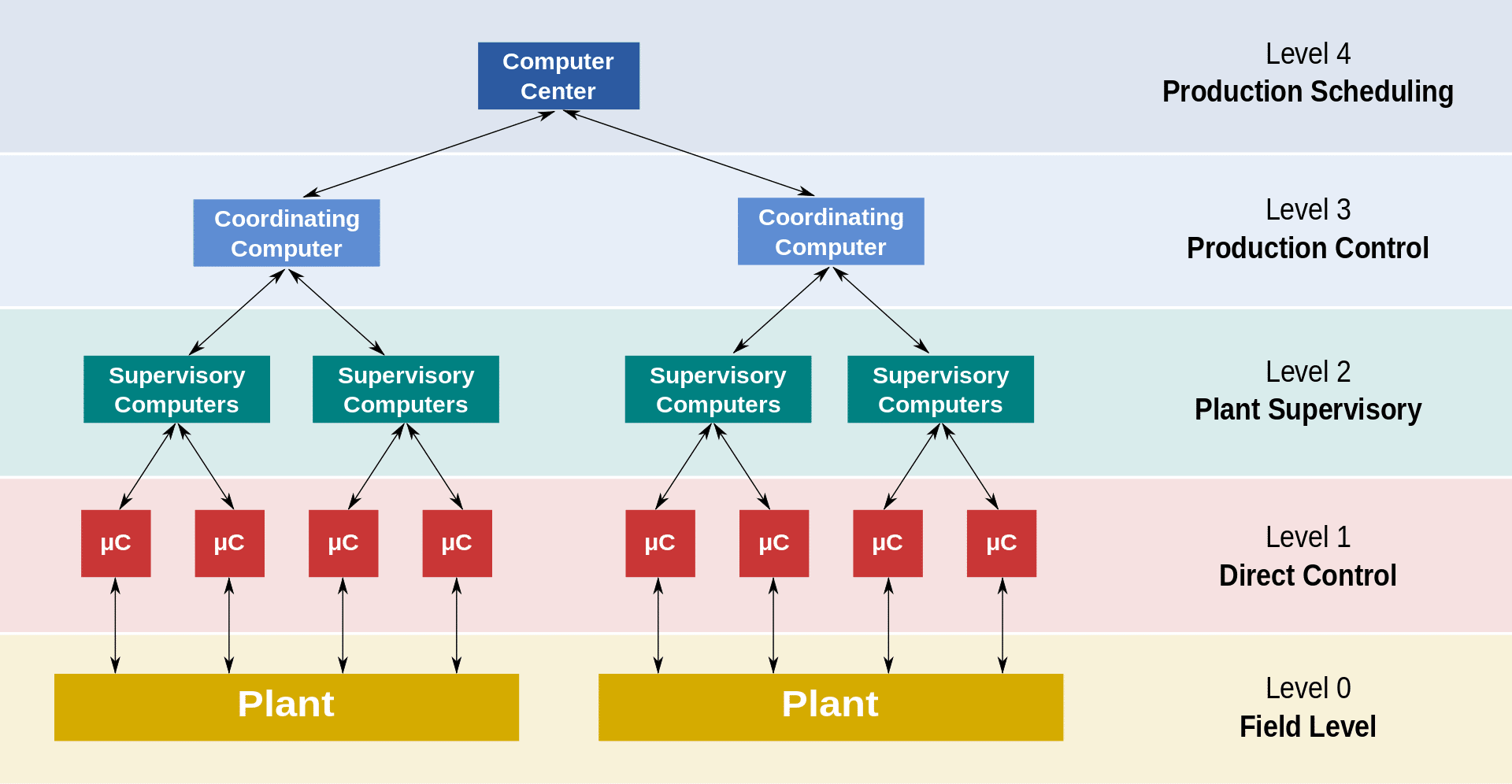

Process Control System An Overview Sciencedirect Topics

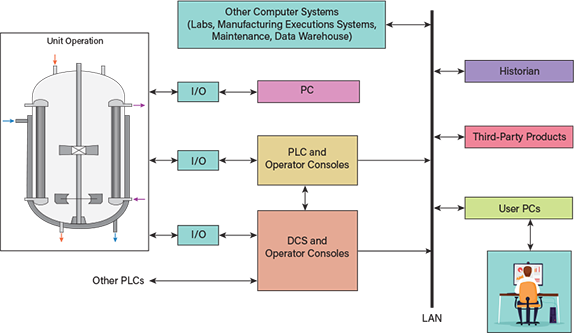

What Is A Distributed Control System Control Station

Process Monitoring An Overview Sciencedirect Topics

News Thermoteknix Thermal Imaging Cameras Thermal Imaging Lancashire

Andon Lcd Industrial Displays Uticor Industrial Display Electronic Schematics Display

Industrial Process Control Systems A New Approach To Education Aiche

Mis Daily Reports Diagnostics Knowledge Bank Can Be Customizable To Specific Requirements Customized Process Engineering Conceptual Design Heat Exchanger

What Is Cmms Preventive Maintenance Management Maintenance

Key Roles Of The Humanresource Human Resources Human Resources Jobs Human Resources Career

Inclusion Of Details In Scot Multiple Disparate Data Sources Like Lead Times Inventory Levels In Transit Time Scots Stock Keeping Unit Process Engineering

Success Stories Power Distribution Network System Scada Developer Network Success Stories Success Power

Quality Assurance High Product Quality Is The Key To Building Satisfied Long Term Customers Product Qu Process Control Customer Complaints Quality Assurance

Key Performance Indicators Infographic Key Performance Indicators Social Media Agile Project Management

0 Response to "RECOMMENDATION OF PROCESS MONITOR IN PALNT OPERATIONS"

Post a Comment